About Boss Laser's CO2 & Fiber Lasers

Cutting Speed & Performance

• High-Speed Motors: Boss Laser systems are engineered with advanced hybrid servo motors that deliver rapid, precise motion. While actual cutting speeds depend on material thickness and type, many models are designed to achieve cutting speeds that can be several times faster than entry‐level systems—for example, many CO₂ machines can run in the range of 30–100 inches per minute on materials like acrylic, wood, and fabric.

• Consistent Energy Delivery: Integrated electronics and intelligent laser energy management help maintain a uniform energy density across the work area, ensuring smooth cuts even at high speeds.

Material Versatility

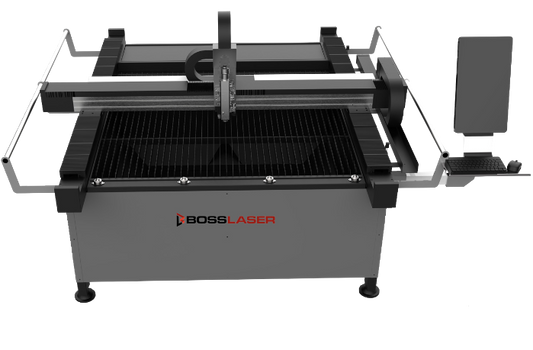

• Wide Material Range: Boss Laser machines are built to process a broad spectrum of materials. They are capable of cutting and engraving more than 20 different types, including:

• Non-Metals: Acrylic, wood, MDF, leather, fabric, paper, rubber, and plastics.

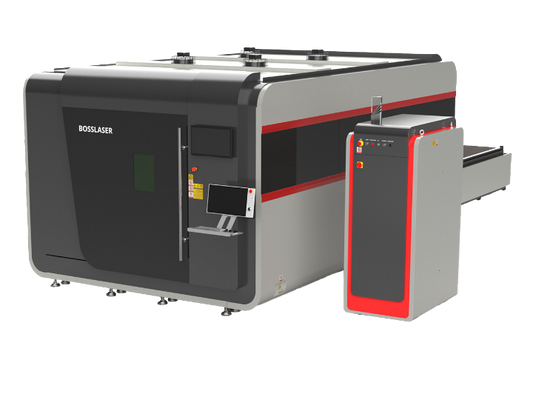

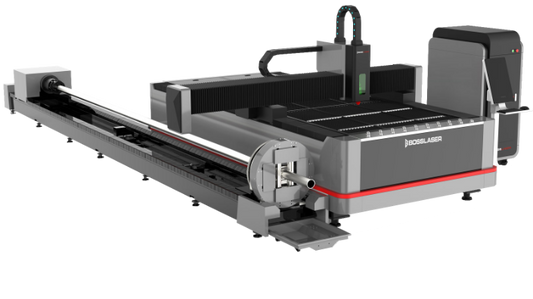

• Metals: Their HP-Series (and fiber-based FC-Series) machines can handle various metals such as stainless steel (up to 18‑ga on some models), aluminum, brass, copper, and even titanium.

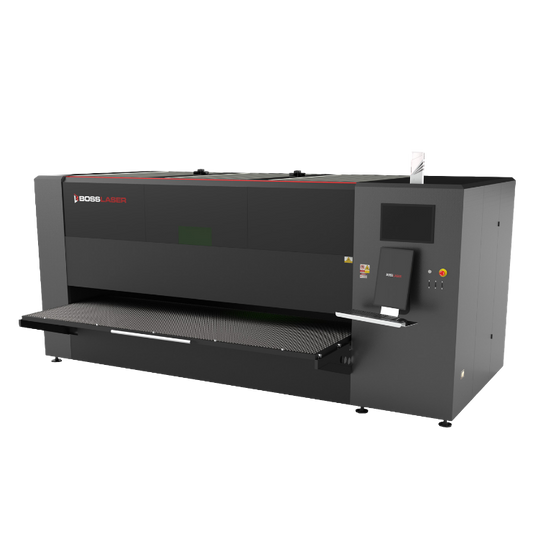

• Application-Specific Models: Different series (LS, HP, FC, FM, UV) are optimized for particular applications—from general engraving and cutting on organic materials to industrial metal cutting with fiber laser systems.

Optical Quality & System Design

• Precision Optics: Boss Industrial Lasers use high-quality optical components (e.g., precision-coated lenses and mirrors) to achieve excellent beam quality (with beam profiles often approaching an M² value close to 1). This ensures a small, consistent focal spot for fine cutting and detailed engraving.

• Narrow Kerf & Detail: The design of the optics results in minimal kerf widths, which is key for precision work. The laser head’s design—often incorporating features for rapid alignment and focus adjustments—helps maintain optimal cutting performance across diverse materials.

• Robust Construction & Maintenance: Boss Laser systems are engineered and assembled in the USA to high industrial standards. Their design emphasizes both long-term durability and ease of maintenance, which includes provisions for quick lens and optical alignment adjustments.